News 036

News

Claas / 23 August 2021

CLAAS launches TRION: a new benchmark for the medium combine harvester class

Press release / (Harsewinkel, D) With the launch of 20 new combine harvesters in the TRION model series, CLAAS is taking another step in its harvesting machinery model initiative which began in 2019. This means that the company has renewed almost its entire combine harvester range in the space of just two years.

The state-of-the-art TRION model series comprises not only 5 and 6-walker machines, but also hybrid combine harvesters with single or twin rotors. Several TERRA TRAC and MONTANA versions are also available. True to the TRION “Fits your farm” motto, the resulting line-up of machines offers a choice of variants and features like no other in this combine harvester class.

Initiated as a result of numerous in-depth discussions with customers, developed hand-in-hand with farmers, contractors and distributors in the world’s key agricultural regions, perfected with the expertise of the CLAAS research and development engineers: the new TRION is another landmark in the evolution of CLAAS combine harvesters and sets new benchmarks in the medium combine harvester performance class.

The unique scope of the line-up of models and features makes it possible to meet practically every customer requirement. The TRION is suited to every market – whether in Europe, North America or South Africa – and is aimed at customer segments ranging from the tradition-conscious family farm to performance-oriented large farms and high-tech contractors. Whether it’s a question of meeting the requirements of 200-hectare farms or businesses with an annual combinable area of 1,000 hectares; whether the crops are wheat, rapeseed, maize, soybeans or rice; whether the terrain is hilly or totally flat: the objective is to deliver maximum threshing efficiency and easy operation in a customer-oriented combination for every farm and all conditions: TRION – Fits your farm.

Four attributes in particular allow the TRION to meet the extremely wide range of requirements of customers all over the world:

- The new TRION is synonymous with a high level of adaptability to the requirements of the individual farm and the particular crop during the harvest – with fast, easy and tool-free crop type changes and a large number of cutterbar types with widths up to 12 m or 12 rows. In addition, the new series is unrivalled in the scope it offers for individualising the specification of the cab and convenience features as well as the running gear and drive system.

- The performance of the TRION under all harvesting conditions means that compromises between efficiency and productivity are a thing of the past. The proven APS threshing technology with JETSTREAM cleaning, a large grain tank and high offloading rates contribute to its impressive capability. A straightforward, efficient and low-maintenance drive train combined with intelligent engine technology featuring DYNAMIC POWER keeps fuel consumption to a minimum.

- The precision of the TRION which results from the use of the latest technologies and assistance systems, such as CEMOS AUTOMATIC for automated harvesting, helps to deliver optimised performance and a high level of operator comfort and convenience, regardless of the size of the farm.

- The reliability of the TRION has been assured by a worldwide testing programme. Straightforward and time-saving customer maintenance tasks combined with a reliable drive train, longer maintenance intervals and excellent drive status monitoring save time and make costs more predictable.

The wide range of wheeled machines, TERRA TRAC and MONTANA models, rounded out by an extensive line-up of cutterbar combinations, allows every farm – whatever its operational profile – to make the right choice without having to compromise.

Two separation concepts, three model series

With the unprecedented variety of machines that make up the three new TRION model series, CLAAS is able to occupy the spectrum from the 258 hp five-walker all the way up to the 435 hp hybrid combine harvester with twin rotors. The 20 new models feature many state-of-the-art assistance systems, provide a very high level of driving comfort and user-friendliness, and are outstandingly efficient.

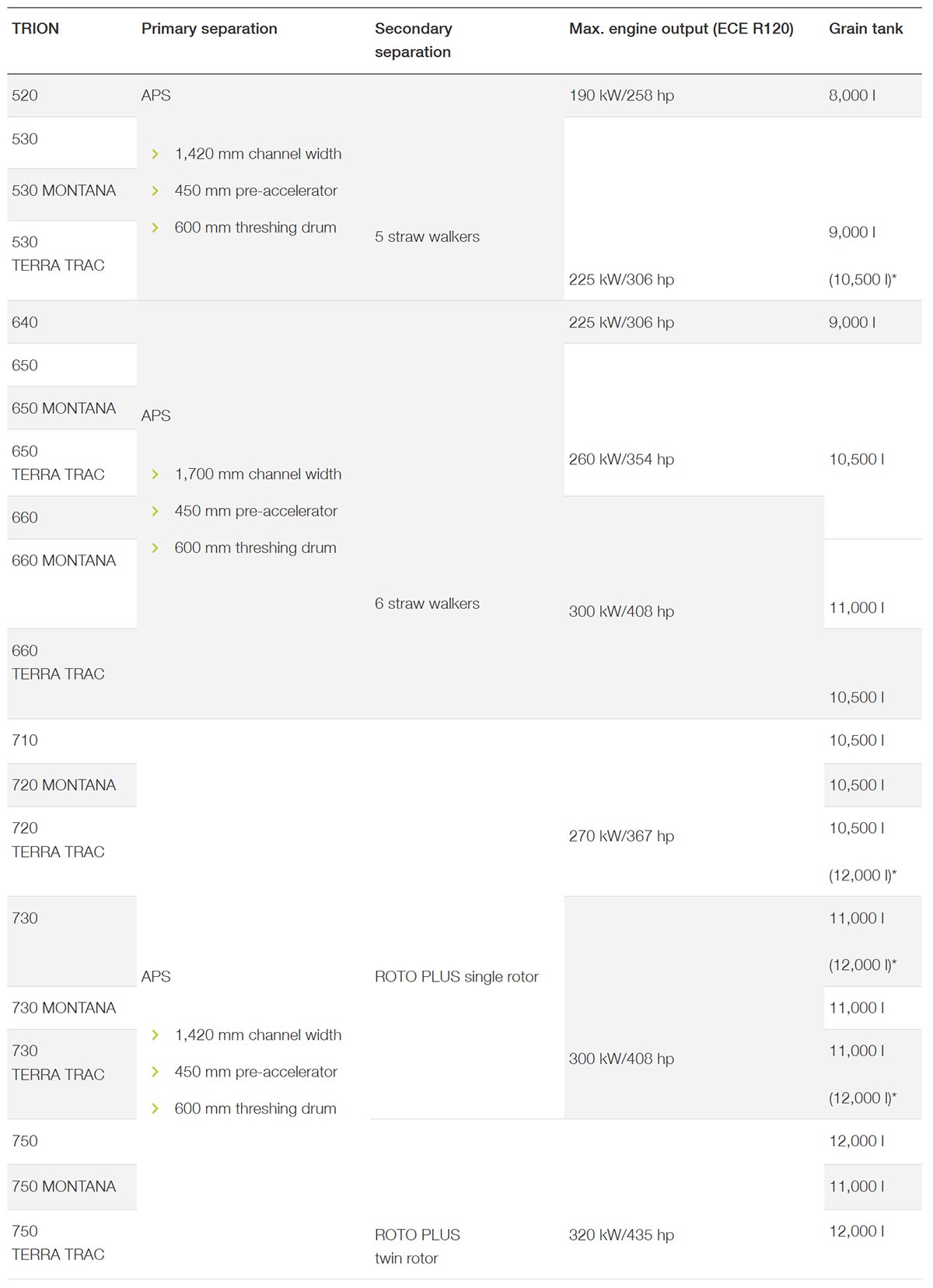

The TRION range essentially comprises three model series with straw-walker and hybrid combine harvesters and two threshing channel widths:

- TRION 500 with 5-walker APS WALKER threshing system; 1,420 mm channel width

- TRION 600 with 6-walker APS WALKER threshing system; 1,700 mm channel width

- TRION 700 with APS HYBRID threshing system (TRION 710 – 730 with ROTO PLUS single rotor, TRION 750 with ROTO PLUS twin rotor); 1,420 mm channel width

As well as bringing a new, wide choice of separator solutions to the performance class they cover, all the model series can be equipped with the very latest features. This means that the catalogue now includes not only six versions with TERRA TRAC crawler tracks, but also another six machines with MONTANA side slope compensation. In addition, all TRION models are equipped with a new premium cab. Reflecting the vast spectrum of possible configurations, which extends all the way up to a high-tech combine harvester, and the many different applications for which the new range is suited, the “Fits your farm” motto of the TRION could not be more appropriate.

Focused on meeting the highest performance requirements

Primary separation in all TRION models is performed by the APS threshing unit with an accelerator drum (450 mm diameter) and a large threshing drum (600 mm diameter) which provides a consistent, high crop flow and allows sustained operation throughout long working days. Some 90 percent of the grains are gently threshed out of the crop in this initial stage. The speeds of all three drums can be adjusted synchronously from the cab via CEBIS. CEBIS is also used for the parallel and synchronous adjustment of the preconcave and threshing concave. Hydraulic overload protection allows operation right up to the performance limit, prevents blockages and also provides protection against damage from foreign objects. If necessary, the three concave segments of the MULTICROP preconcave, which is designed for many threshable crops and threshing conditions, can simply be replaced through the stone trap. The main concave can be equipped with various concave segments, as required, with one concave segment designed as an easily swappable unit.

Secondary separation in the TRION 500 and TRION 600 is performed by five or six straw walkers with respective separation areas of 7.48 and 6.25 m2. These models are equipped as standard with the MULTIFINGER SEPARATION SYSTEM (MSS) which fluffs the straw mass evenly, thereby increasing the separation performance significantly, especially when dealing with a high level of straw moisture or volunteers. Secondary separation in both the TRION 720 and TRION 730 is handled by a single rotor. By contrast, the flagship of the model series, the TRION 750, uses twin rotors for secondary separation. In all TRION models with APS HYBRID and ROTO PLUS, the speed of the rotors can be varied from the cab infinitely and independently of the speed of the APS threshing unit. Hydraulic rotor flap adjustment (TRION 720/730: manual adjustment available as an option) makes it possible to close up to four rotor segments, thereby reducing the load on the sieve pan when dealing with dry straw.

JET STREAM cleaning with 3D/4D slope compensation

In order to cope with the high throughput rates, all TRION models are equipped with an extremely efficient JET STREAM cleaning system with a turbine fan, hydraulic fan speed variator and a dual-ventilated first step to provide pre-cleaning. The upper and lower sieves have a combined total sieve area of 5.1 m2 in the TRION 500 and TRION 700 as well as 5.8 m2 in the TRION 600. Thanks to 3D cleaning with active transverse control, the full cleaning performance is maintained up to a 20% transverse incline. During up- and downhill threshing, AUTO SLOPE adjusts the fan speed automatically. In the case of the TRION 700, the optional 4D cleaning system also ensures constant performance when operating on slopes.

CEMOS assistance systems to meet individual requirements

All TRION models can be equipped as required with various automatic and operator assistance systems from the CEMOS AUTOMATIC and CEMOS DIALOG ranges which not only enhance performance but also optimise efficiency and threshing quality while reducing the operator’s workload.

- AUTO CROP FLOW detects load peaks in the primary and secondary separation stages as well as at engine level and reduces the flow of material into the threshing unit if necessary.

- CRUISE PILOT takes automatic control of the ground speed in accordance with one of three preselected modes: Cruise control for a constant ground speed, Constant throughput for consistent loading of all the key assemblies, even under drastically changing harvesting conditions, and Maximum throughput with loss monitoring for consistent threshing at the machine’s performance limit.

- AUTO SLOPE: adjusts the speed of the turbine fan on the basis of the longitudinal tilt of the TRION on slopes so that the cleaning performance remains stable.

- CEMOS AUTO CLEANING: the fan speed and the sieve openings of the upper and lower sieve are automatically adjusted to changing threshing conditions.

- CEMOS AUTO THRESHING: the threshing concave clearance and the speed of the APS threshing unit are automatically adjusted to the threshing conditions.

- CEMOS AUTO SEPARATION: this function of the TRION with APS HYBRID automatically adjusts the rotor speed and the position of the rotor flaps to changing harvesting conditions.

12,000 l grain tank with 130 l/s unloading

High throughput rates require equally high performance when it comes to unloading – and correspondingly large grain tanks, too. The grain tank sizes of 8,000, 9,000, 10,500, 11,000 or 12,000 litres vary in accordance with the model and version. Unloading rates range from 90 to 130 l/s. The large 105-degree pivot angle of the unloading tube allows the operator to have an excellent view of the spout during unloading. Available as an option, the PROFI CAM provides a direct, wide-angle view into the trailer or body of the transport vehicle and so enables the operator to manage the unloading process with even greater anticipation and accuracy. An optional pivoting spout which can be adjusted via the CMOTION multifunction control lever makes extremely precise unloading possible, even while on the move.

Powerful straw choppers

If the straw is to remain in the field, the available straw choppers and spreaders can be counted on to do an excellent job. As an alternative to the regular STANDARD CUT unit, which has 52 knives in the TRION 500 and 700 with a narrow threshing channel and 64 knives in the TRION 600 with a wide threshing channel, the TRION models can be equipped with the SPECIAL CUT straw choppers with 72 or 88 knives respectively. The spreading width and direction can be adjusted manually or, as an option, electrically via CEBIS.

The power spreader available for large working widths spreads the straw and chaff reliably and evenly across the entire working width. Automatic discharge direction adjustment, which can be specified for both the standard spreader and the power spreader, automatically corrects the discharge direction in accordance with the set sensitivity level to compensate for crosswind and sloping terrain and so maintain even distribution.

New engines – proven efficiency

All four TRION model series are powered by the latest generation of Cummins six-cylinder engines: the TRION 500 series as well as the TRION 640 have the Cummins B6.7 unit which meets the Stage V standard and has a displacement of 6.7 l, while the TRION 650, TRION 660 and the TRION 700 series are powered by the Cummins L9, a Stage V unit with a displacement of 8.9 l. The rated engine speed of the common-rail power plants is just 1,900 rpm, with road travel at a quiet and fuel-saving 1,650 rpm. What’s more, all engines have the DYNAMIC POWER automatic output adjustment system. If the full engine output is not required, when swathing, for example, the engine control unit reduces the output – and therefore the amount of diesel injected – to the required level. This intelligent control system on its own is capable of saving up to 10 percent of fuel costs. Add to this the effect of the low engine revs and it is clear that, in terms of efficiency, too, the TRION models are everything one would expect from a CLAAS combine harvester.

The TRION 500 and TRION 600 have a diesel capacity of 600 and 800 l respectively, while the TRION 700 can be specified with a fuel tank of 800 or 1,000 l. Depending on the model, 80 or 100 l of AdBlue can be carried for the emission control system.

Six MONTANA and TERRA TRAC versions

The availability of models with MONTANA side slope compensation and TERRA TRAC crawler tracks is greater than ever with the TRION. The chassis of the TRION MONTANA machines is able to compensate for side slopes of up to 18 percent and longitudinal slopes of up to 6 percent. In addition, the TRION MONTANA machines have POWER TRAC all-wheel drive, AUTO SLOPE to manage cleaning performance on slopes and an optional electrically engageable differential lock for the front wheels. Common to all chassis types are two drive ranges for each of the two speeds.

TERRA TRAC crawler tracks in three track widths from 635 mm to 890 mm are available for six models in the new TRION series, among them the TRION 530 TERRA TRAC with five straw walkers. The latter, like the TRION 700 TERRA TRAC, remains within an external width of 3.29 m when running on narrow tracks and within 3.49 m on 735 mm tracks. The 600 series of TRION TERRA TRAC models have an external width of 3.49 m with the 635 mm tracks. All TERRA TRAC models, like the wheeled machines, are capable of road travel at up to 30 km/h.

Wide range of front attachments ex factory

The TRION models can be combined with a large number of CLAAS front attachments. In addition to the CERIO auger cutterbars with a rigid table, the range includes VARIO cutterbars, CONVIO draper cutterbars and folding cutterbars. For low-growing crops, such as peas or soybeans, in particular, the line-up comprises the MAXFLEX series with an intake auger and the CONVIO FLEX draper, both of which have a flexible table. The range of cutterbars is complemented by the CORIO and CORIO CONSPEED grain maize picker front attachments as well as the SUNSPEED for threshing sunflowers. In relevant markets, such as Canada, the SWATH UP pickup can also be supplied. Thanks to automatic front attachment detection, the TRION always knows which front attachment is fitted and is able to make the necessary adjustments to the machine settings automatically.

The feeder housing can be supplied with either a fixed cutting angle, a mechanically adjustable cutting angle or a cutting angle which can be adjusted hydraulically from the operator’s seat. It is also possible to order a belt conveyor as an alternative to the chain conveyor in the feeder housing. As well as running more smoothly and quietly, belt conveyors have a longer service life and require less maintenance. Customers also have the choice of an open or closed guide roller. Hydraulic reversing for the front attachment is standard, as is the new “slow feeding” function.

The latest in advanced cab design

Another highlight of the TRION model series is the new cab. It offers more space, especially headroom and legroom, and can be equipped with an optional leather seat which swivels 30 degrees to both sides for an optimal seating position at all times. Optional footrests enable a number of relaxed seating positions for the operator. A larger windscreen and side windows with narrower A-pillars make for an excellent view of the front attachment and the surroundings. The 12-inch CEBIS terminal with a high-resolution, high-contrast HD display ensures outstanding legibility under all light conditions and provides three individually adjustable main display areas. CEMOS DIALOG and CEMOS AUTOMATIC are now integrated in CEBIS. The terminal can be operated via the touchscreen and rotary push switches. It is also possible to access all the threshing unit and cleaning settings by means of direct access buttons on the right of the control armrest.

The CEBIS terminal and armrest can be adjusted independently of each other to provide an optimal ergonomic response to the operator’s needs. And with the CMOTION control lever, which is available as an alternative to the standard ground speed control lever, the operator always has the key functions – including up to seven individually programmable favourite settings – at their fingertips for a rapid response.

A 30-litre cool box, an optional 360-degree LED lighting package and a 360-degree windscreen wiper complete the comprehensive package of features.

Four steering systems and new CEMIS 1200

Customers have a choice of four automatic steering systems. The LASER PILOT steers by using the left-hand edge of the crop as its point of reference. The FIELD SCANNER is fitted on the roof of the cab and steers the TRION by optically sensing the edges of the crop (left and right possible) and tramlines. During grain maize harvesting, the TRION is steered by the AUTO PILOT on the CORIO and CORIO CONSPEED pickers.

The fourth option is the GPS PILOT with satellite-based navigation. The new CEMIS 1200 terminal with a 12-inch screen is available for this function. It offers 2D and 3D views, online task management and documentation with data export via TELEMATICS or USB stick, real-time yield mapping and yield data displays.

Full availability with effect from the 2022 harvest

All TRION models are live in the CLAAS product configurator in the European markets with immediate effect and can be ordered for the 2022 harvest; introduction of the model range in North America and Russia is scheduled in the medium term.

The full range of the proven TUCANO 300, 400 and 500 model series will continue to be manufactured and sold in Russia until the TRION is introduced.

The wide range of TRION models at a glance:

*optional

further information: Claas, www.claas.com